Removing Slide

- juniustaylor

- Elite member

- Posts: 1409

- Joined: February 9th, 2010, 10:56 pm

- Location: KV, MO

- Contact:

Re: Removing Slide

What year is your pistol Weasel? I'll take some pictures of mine and put them on here so you can compare them against your pistol.

- juniustaylor

- Elite member

- Posts: 1409

- Joined: February 9th, 2010, 10:56 pm

- Location: KV, MO

- Contact:

Re: Removing Slide

Pistol on SAFE. The disconnector is pushing the trigger bar down and allows the trigger to be pressed/depressed with no resistance. The disconnector is also pushing the sear forward so it cannot engage the hammer.

Pistol on FIRE w/ hammer not cocked. The measurement at the closest point between the trigger bar and the disconnector is 1mm.

Pistol on FIRE w/ hammer cocked. The measurement at the closest point between the trigger bar and the disconnector is ~2.5mm.

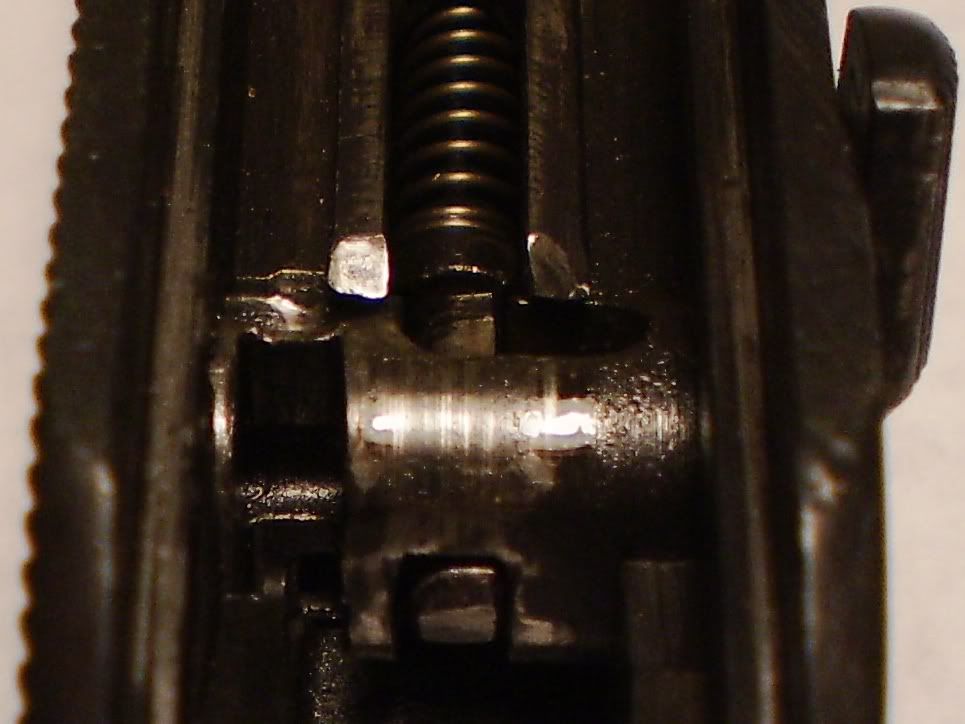

Here is my disconnector. The part contacted is the side on the left (pistol forward). It should be taller than the right (pistol aft). The roundedness on the aft side of the disconnector doesn't affect anything.

Here's my safety cam. Mine is slightly worn, but it doesn't look too bad.

I hope these pictures help you out. Take them for what they're worth. My trigger bar appears different than yours.

Here's a video to kind of simulate what happens when the safety is switched to SAFE with the hammer cocked (simulate decock). Do not pay any attention to the trigger bar, it has no function in dealing with the decock, only during actual firing (actuation of the trigger). This will probably send you to Photobucket to view, so just click Back to return to this thread.

The important parts are the disconnector and the actual sear. The sear is moved forward to disengage it from the shelf on the hammer. With the heavier recoil spring installed, if it were to case the rear of the slide to lift slightly (depending on slop in the slide tracks) it could cause your worn safety cam and worn disconnector to not push in enough to disengage the sear. This is all theoretical. Play around with it a bit and see what you can find out. I don't know if bt2010 still has a disconnector or not. You can always try to give him an email and see if he sold it. If he did, ask him for the buyer's info and try to ask if you could purchase it from them. It's just a thought...

-

normsutton

- Global moderator

- Posts: 3575

- Joined: February 26th, 2006, 6:59 am

- Location: LAKELAND FL.

Re: Removing Slide

juniustaylor

Weasel

I have read this tread 5 times, you guys don't write bills for congress do you, how did you get from not getting the recoil springs on to the safety drum and the disconnector , you are going to have worn part's do not grind anything on these guns , they are used guns , do not put any grease under the disconnector , it will not work properly , only put grease on the rails of the gun, make sure there is no grease in the frame of the gun, use only oil for lubrication in the frame's , yes when loading these guns ,load them with the safety off , it is a de cocker and a safety,

read the tag that came with your gun

when you make changes to these guns do at your own risk,

NORM

Weasel

I have read this tread 5 times, you guys don't write bills for congress do you, how did you get from not getting the recoil springs on to the safety drum and the disconnector , you are going to have worn part's do not grind anything on these guns , they are used guns , do not put any grease under the disconnector , it will not work properly , only put grease on the rails of the gun, make sure there is no grease in the frame of the gun, use only oil for lubrication in the frame's , yes when loading these guns ,load them with the safety off , it is a de cocker and a safety,

read the tag that came with your gun

when you make changes to these guns do at your own risk,

NORM

NORMSUTTON@AOL.COM

N.R.A. LIFE MEMBER 1976

N.R.A. LIFE MEMBER 1976

Re: Removing Slide

Thank You Norm for putting in the proper words.

Boomer

Boomer

- juniustaylor

- Elite member

- Posts: 1409

- Joined: February 9th, 2010, 10:56 pm

- Location: KV, MO

- Contact:

Re: Removing Slide

Not sure about Weasel's gun, but mine did not come with a hang tag that removes responsibility from the seller to the end user.

Yes, the original post was about having problems with the spring and removing the slide. Weasel did mention this...

Anyway, I see nothing wrong with any advice, pictures, etc. that I have offered here. However, thanks Norm for the advice on the lubrication procedures.

Yes, the original post was about having problems with the spring and removing the slide. Weasel did mention this...

That is how we got into discussing his safety and disconnector. He never directly stated that he was going to grind on anything and neither did I suggest he do so. He only talked about grinding the new spring. He mentioned modifying a part but seems to have decided against it.Weasel640 wrote:One thing that I did notice; while with the odd fitting spring on, it misaligned the slide just enough to cause the safety to NOT decock the P-64 50% of the time. With the original spring back on the decocking action is back to 100%. Just something to keep in mind. Recoil spring fit may affect the decocking action or any other action for that matter.

Anyway, I see nothing wrong with any advice, pictures, etc. that I have offered here. However, thanks Norm for the advice on the lubrication procedures.

Re: Removing Slide

juniustaylor,

Sorry I didn't answer this, it is a 1976 model.

I got a chance to grind the Wolff recoil spring on a belt sander at work, the ends are now flat and match the original spring. It now fits the P-64 perfect and the previous symptoms seem to have gone.

Norm,

No the topic is not originally about the safety, I did not know I was being judged on my strict ability to stay on topic. However I was having the exact problem that cichlid had mentioned due excess material on the replacement Wolff recoil spring. The topic progressed because I mentioned a parallel symptom/problem caused by the Wolff recoil spring not fitting properly. The only grinding that was suggested was to the Wolff recoil spring, the exact modification that cichlid had mentioned.

I don't know why you would tell us not to put any grease anywhere in the frame. The assemble instructions here (http://www.p64resource.com/board/P64_%20Assembly.pdf) page 58 clearly tells you to add grease to the trigger bar where it comes in contact with the disconnector within the frame. Are you saying that this source is wrong?

Additionally no tags came with this gun. But right here in the manual (http://www.p64resource.com/board/P64Manual.pdf), page 5, To unload a P-64, it would have you let the slide forward while on safe. This is the type of unnecessary wear to the safety I mentioned avoiding.

Weasel

Sorry I didn't answer this, it is a 1976 model.

I got a chance to grind the Wolff recoil spring on a belt sander at work, the ends are now flat and match the original spring. It now fits the P-64 perfect and the previous symptoms seem to have gone.

Norm,

No the topic is not originally about the safety, I did not know I was being judged on my strict ability to stay on topic. However I was having the exact problem that cichlid had mentioned due excess material on the replacement Wolff recoil spring. The topic progressed because I mentioned a parallel symptom/problem caused by the Wolff recoil spring not fitting properly. The only grinding that was suggested was to the Wolff recoil spring, the exact modification that cichlid had mentioned.

I don't know why you would tell us not to put any grease anywhere in the frame. The assemble instructions here (http://www.p64resource.com/board/P64_%20Assembly.pdf) page 58 clearly tells you to add grease to the trigger bar where it comes in contact with the disconnector within the frame. Are you saying that this source is wrong?

Additionally no tags came with this gun. But right here in the manual (http://www.p64resource.com/board/P64Manual.pdf), page 5, To unload a P-64, it would have you let the slide forward while on safe. This is the type of unnecessary wear to the safety I mentioned avoiding.

Weasel

Re: Removing Slide

Weasel,

Welcome to the forum - we're glad to have you.

I'll not speak for Norm, but the manual is the reprint that comes with most of these guns (at least it used to). The tag he posted used to come with most milsurp guns; I guess it doesn't anymore. The reprint manual is there in case you didn't get one with your pistol, and as a reference only. We did not make it, nor do we agree with everything in it. With that said, there are some things that can always be done better, and the order in which you field strip a weapon can make a difference, particularly wear on certain parts as you have noted.

The assembly PDF was graciously done independently by a member of the board. It's meant to be used as a guide to fully detail strip your weapon. It's not intended to be an owner's manual or a how-to on lube. It's hard to know when and what to edit sometimes, especially when you have 3 administrative users and 2300 members, unless someone points it out. Perhaps a second version of the PDF is in order.

Consider experienced advice here on the forum to trump the pdf's on the site.

I'll start a working on compiling a new pdf next week.

Thanks!

Welcome to the forum - we're glad to have you.

I'll not speak for Norm, but the manual is the reprint that comes with most of these guns (at least it used to). The tag he posted used to come with most milsurp guns; I guess it doesn't anymore. The reprint manual is there in case you didn't get one with your pistol, and as a reference only. We did not make it, nor do we agree with everything in it. With that said, there are some things that can always be done better, and the order in which you field strip a weapon can make a difference, particularly wear on certain parts as you have noted.

The assembly PDF was graciously done independently by a member of the board. It's meant to be used as a guide to fully detail strip your weapon. It's not intended to be an owner's manual or a how-to on lube. It's hard to know when and what to edit sometimes, especially when you have 3 administrative users and 2300 members, unless someone points it out. Perhaps a second version of the PDF is in order.

Consider experienced advice here on the forum to trump the pdf's on the site.

I'll start a working on compiling a new pdf next week.

Thanks!

Re: Removing Slide

I my book, I would not even shoot a Mil Surplus pistol that looked that nasty on the inside until I stipped, cleaned, polished and inspected every part for metal integrity first.

That just my way of doing things though!

That just my way of doing things though!

http://www.usgunleather.com

http://www.usgunleather.com