I've had my eye on a P64 for a while and have been reading lots of great posts on this board recently. Thanks to everyone for their contributions. A couple of days ago I had the chance to trade off a FEG P9R which I absolutely HATED for a P64 (1976) at the local Gander Mountain. I normally don't deal with them in terms of firearms, but hey.

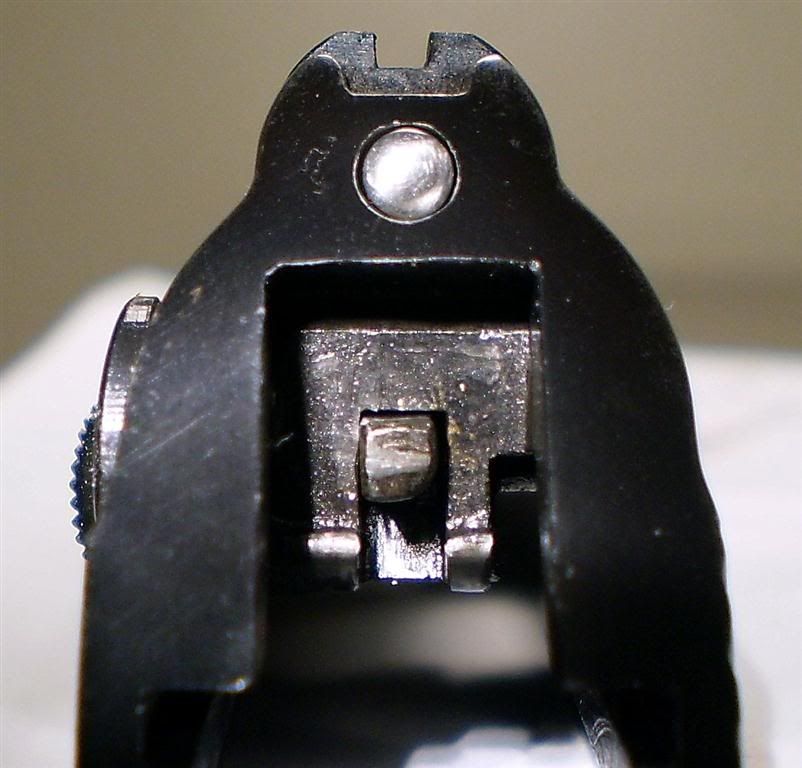

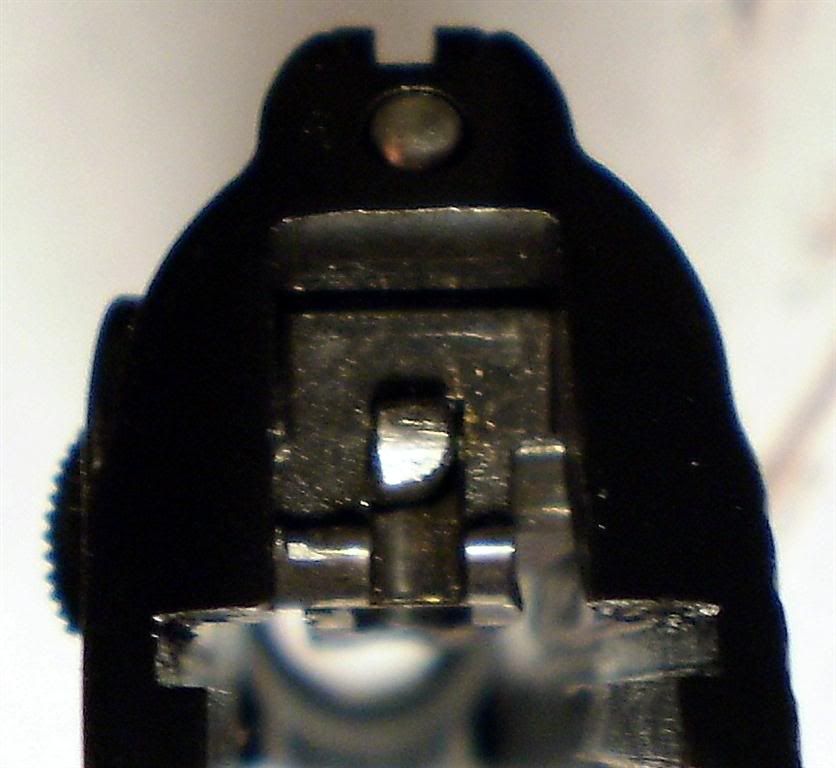

They had two P64s on hand, one of which seemed to be in just slightly better condition than the other, and neither appeared to have any problems. After getting it home and looking at it more closely, I noticed that the safety, whether on or off, seems to slope slightly to the right when viewed from the rear:

I took the safety, detent, spring, and firing pin out to make sure there was no crud hiding and to be sure all surfaces were OK. After re-assembling the safety mechanism the 'cant' is still present. There doesn't seem to be any functional problem with the weapon and when testing with a pencil down the barrel the firing pin is making rather epic contact.

My question is, is the canted safety normal, or should I go back up and check out the other P64 and use my 30 days to trade them out?

Edit: Made the title sound less like a request for gun safety tips.

http://www.usgunleather.com

http://www.usgunleather.com