Page 1 of 2

Safety/Decocker = Very Stiff

Posted: November 10th, 2011, 2:46 pm

by whgraham

Hello All.

Having some trouble with the effort it takes to engage the decocker/safety. I'd like it to be firm, but still be able to work with just a thumb. I can work it that way, but I've really got to muscle that thing around, both to decocker and move back to fire.

To make some improvements here, what should I be looking at. Suggestions?

Also, like all of them, DA is horrible. SA is great. I don't think it's had a mainspring replacement installed. I'm interested in doing so, but worry about the SA then being ridiculously light. Are there other areas to address in the trigger group that could yield any improvement in DA trigger mode?

Thanks.

Re: Safety/Decocker = Very Stiff

Posted: November 10th, 2011, 3:50 pm

by Curly1

Check out this thread.

viewtopic.php?f=3&t=4173

Yes SA after the spring change is very hair trigger IMO.

Re: Safety/Decocker = Very Stiff

Posted: November 10th, 2011, 7:50 pm

by juniustaylor

There are a couple little things you can try for the safety. You can take it out and try to remove any burrs that may be on the inside of the slide where the safety goes into, it's a little cupped out area on the right side of the slide. As Curly said, you can look to see if the bottom of the slide isn't peened into the safety. You can also lightly remove some of the point from the safety detent and make it a tad more rounded so it doesn't take so much effort to get it out of the indents on the safety. Is it hard to get it out of the safe and fire positions or is is rough all around to get it from one to the other?

For the mainspring, no matter what you do, it's going to affect both SA and DA. If you lighten the mainspring with a reduced power one, it's going to affect both. It does make the SA pretty darn light, but you get used to it after a while. Keep the finger off the trigger and follow-thru with the squeeze and you shouldn't have any problems. I don't think I've ever had a double-fire with my 17# spring that I can recall. It just has to do with the mechanical advantage in the trigger group where the sear contacts the hammer and how the trigger bar all fits in there. I don't see any feasible modification being done to stiffen SA and lighten DA.

Re: Safety/Decocker = Very Stiff

Posted: November 10th, 2011, 9:27 pm

by whgraham

juniustaylor wrote:Is it hard to get it out of the safe and fire positions or is is rough all around to get it from one to the other?

Both directions. Hard to de-cock and hard to put back in fire position.

Thanks.

Re: Safety/Decocker = Very Stiff

Posted: November 10th, 2011, 9:48 pm

by juniustaylor

Does it feel gritty when in motion from one position to the other? Or is it just hard to get out of each position but moves freely to the next position? Sorry for the questions, just wanting to understand completely.

Re: Safety/Decocker = Very Stiff

Posted: November 10th, 2011, 11:18 pm

by whgraham

Not really gritty. Just hard to get going each direction, but in travel it feels fine.

One other thing that may be related: When engaging the safety, to get the hammer to de-cock you kind of have to over-travel and scoot the level back ever so slightly back towards the fire position (really just a little, but consistent).

Re: Safety/Decocker = Very Stiff

Posted: November 10th, 2011, 11:33 pm

by juniustaylor

Have you taken the safety out and gave everything in there a good cleaning and look-over? You may do that if you haven't. Remove any burrs, lightly lube, and try again. As for the decocking, either the cam on the safety is a bit worn or the disconnector is worn. May require a good look-see. What you told me is what I thought I was understanding. It is hard to get it out of position, but in motion to the next position it is smooth. May rule out peening of the slide. They look like little fingers right below the safety on the bottom of the slide. Make sure they're not interfering. You may just have to do some rounding on the safety detent so it's more ball shape than pointed. That makes it easier to overcome the indent on each extreme of the safety for SAFE and FIRE.

Re: Safety/Decocker = Very Stiff

Posted: November 10th, 2011, 11:35 pm

by juniustaylor

This is a video I made on getting the safety out if you haven't done it.

http://www.youtube.com/watch?v=FCHgwc0GGa0

If you've got forceps like I'm using in the video, you can just leave them clamped on the firing pin and do the inspection/work you need to do with the safety or detent. You can then just reinstall them and release the forceps for the firing pin to reset back into its proper position.

Re: Safety/Decocker = Very Stiff

Posted: November 11th, 2011, 10:57 am

by whgraham

juniustaylor wrote:look to see if the bottom of the slide isn't peened into the safety.

The prongs are pretty sharp and seem to press fairly hard against the safety part.

I did take it apart last night. The plunger had a pronounced point on it, and the detents seem extreem (diamond shaped, sharp edges, and deep).

Re: Safety/Decocker = Very Stiff

Posted: November 13th, 2011, 1:12 pm

by 68gmcfan

I am having the same problem, my moves freely and then halfway through travel is stiff, both ways. It is a 1976 hand select in like new condition from Aims, so it appears to not have been shot much.

Re: Safety/Decocker = Very Stiff

Posted: November 14th, 2011, 11:05 am

by whgraham

Mine's a 1974. Looks like it was carried a fair bit, but not shot much as well.

I'm going to have another go at smoothing the safety surfaces and creating a channel for the safety detent tonight. Hope it helps.

I don't have weak thumbs, but it does need to be a little easier to work back and forth.

One thing I was wondering is if the hammer spring stiffness could have an effect on this as well, since the you're decocking the hammer with the safety. I'd think that if the spring that you are removing the pressure from is exceedingly strong, that releasing it would be harder to do.

Re: Safety/Decocker = Very Stiff

Posted: November 14th, 2011, 11:19 am

by juniustaylor

whgraham, if I recall correctly, the mainspring (hammer spring) doesn't really have any bearing on the decocker motion. I think it was all in the sear spring. With the slide off, cock the hammer back.

Put your finger over the hammer to keep it from slamming forward. Now, push the disconnector down and you should see the sear mechanism directly in front of the hammer move a bit. The actual function of pushing the disconnector down requires little effort and is further reduced with the mechanical force of the safety pushing it down. You can make sure it's safety only by having the slide off and just try moving the safety back and forth with it off.

You can take the grips off so you can see the innards on the right hand side of the grip. You can watch the disconnector push down and disengage the sear.

I'm not sure that making a channel on the safety would be the best option. You could try rounding the point on the detent. That will remove some overall length of it and a ball shape is a bit easier than the pointed shape to get out of those sharp diamond-shaped indents.

Something like this, but not as exaggerated.

(The one on the left is original shape, the one on the right is rounded.) You can use a file or a dremel-type tool.

Good luck!

Re: Safety/Decocker = Very Stiff

Posted: November 14th, 2011, 11:25 am

by juniustaylor

The only reason I suggest modifying the detent and not the safety is:

Detent: $5

Safety: $30+

There is a great price difference between the two. I'll try to take a picture of my detent tonight. It doesn't take long to get those pieces out of the slide.

Re: Safety/Decocker = Very Stiff

Posted: November 14th, 2011, 11:28 am

by juniustaylor

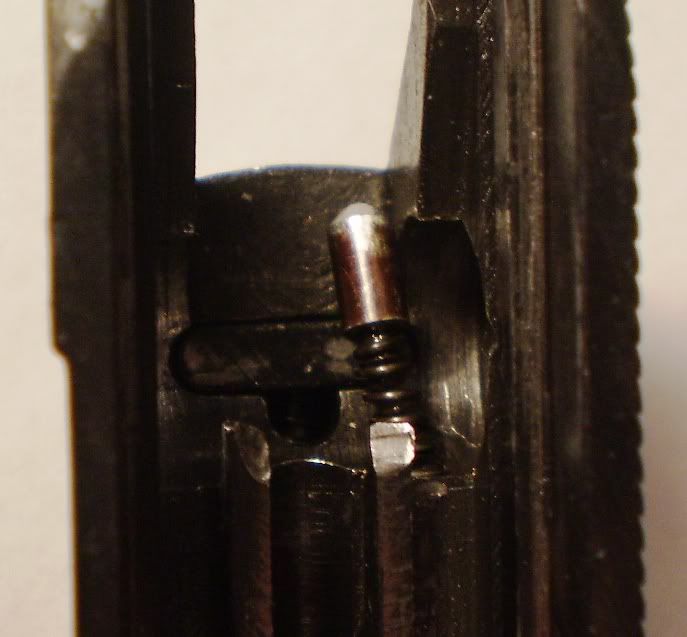

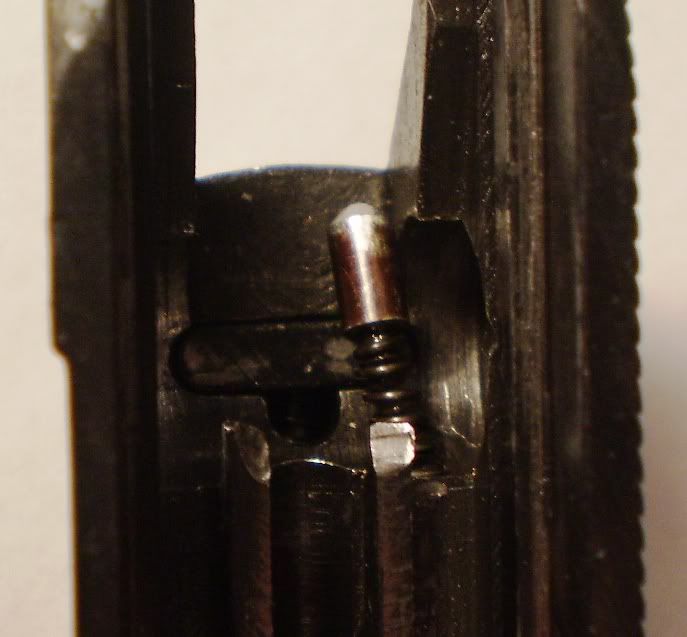

I did find this picture. You can lightly tell that it does not have a pronounced point on the tip. It is more rounded in appearance.

Re: Safety/Decocker = Very Stiff

Posted: November 14th, 2011, 12:03 pm

by whgraham

Thanks for the replies.

I'll focus on the plunger.

With the detents, I was just going to smooth the sides down a little, but not make a groove between the two depressions, so the plunger could slide out a little easier, kind of like a ramp.